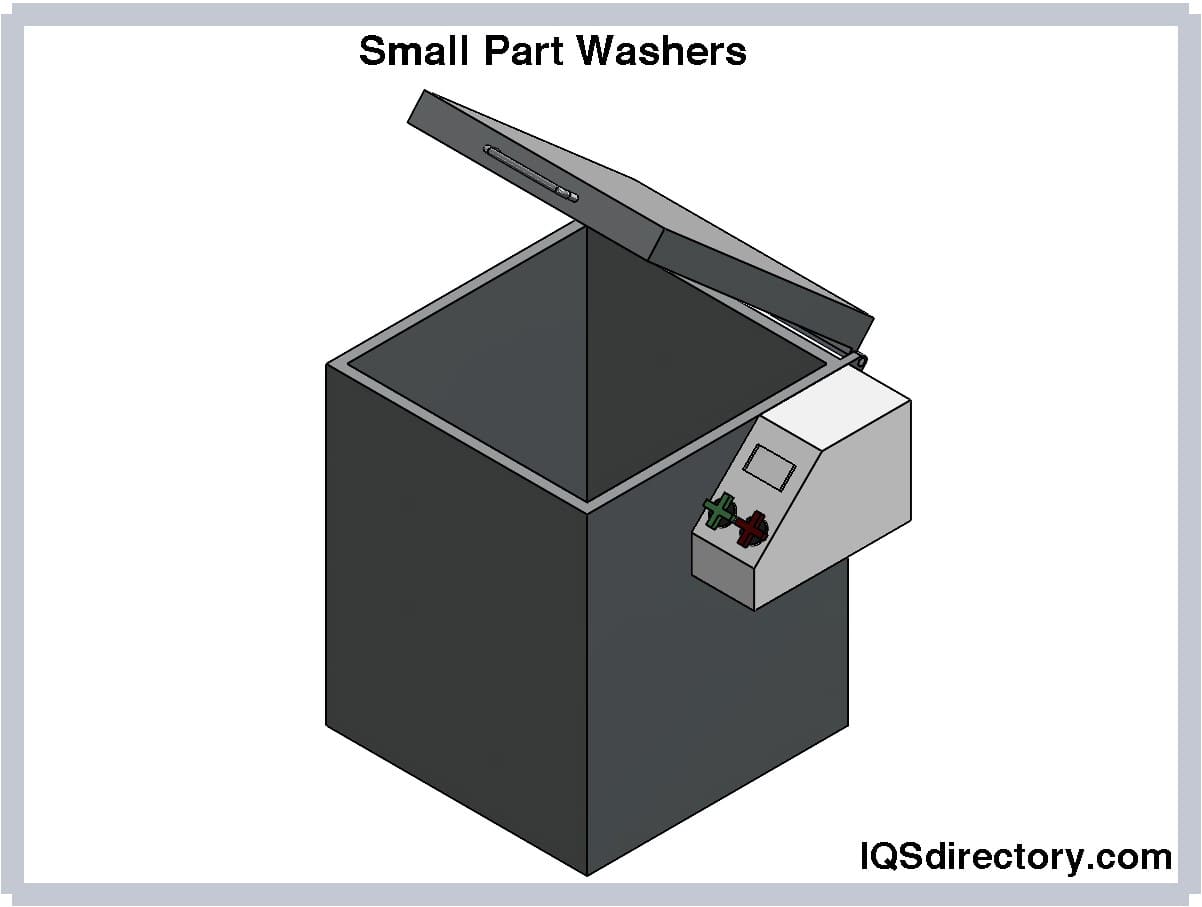

Small Parts Washers

A small parts washer is a cleaning innovation for small part producers. A small parts washer is a small, continuously producing inclined conveyorized washing device that is especially suited for cleaning at the point of manufacture. They are ideal for cleaning tiny components like stampings, bearings, and screw machine items. This small conveyorized system is designed for one-at-a-time, continuous part cleaning at the manufacturing facility. Read More…

Alliance Manufacturing, Inc. specializes in the design, engineering, and manufacturing of aqueous parts washers and parts cleaning systems for the industrial products market. Our engineers have developed a full line of aqueous parts cleaning systems, including belt, chain, monorail, and more.

Niagara Systems LLC has offered turnkey custom parts washing systems for over 80 years. With our customization capabilities, our parts washing systems stand out from the competition.

Nobody knows aqueous parts washers as we do! At Better Engineering, we manufacture sustainable Cabinet/turntable parts washers, Inline cleaning systems, conveyor parts washers, ultrasonic parts cleaner, Dunnage wash systems, Drum washers, Carousel washers, Tunnel, and Monorail Parts Washers in the United States using only quality metal. Our systems are built to high-quality standards; we offer...

We are industry leaders and innovators in the world of parts washers. We offer an extensive list of parts washing equipment, from automotive washers to precision washers for medical industries.

Great Lakes Finishing Equipment, Inc. specializes in supplying parts washers for even the most demanding cleaning jobs. Equipment includes table washers, drum washers, aqueous rotary baskets, aqueous belt washing systems, & more. Let our parts washing specialists assist you with your specific washing applications. Contact us today for all of your parts washer needs.

At Automated Cleaning Technologies (ACT), we excel in providing superior industrial parts washers that meet the diverse needs of various industries. Our expertise ensures that no matter your parts specifications, we have the right solution to tackle the job effectively. We take pride in our ability to deliver reliable, high-performance washers designed to handle even the most demanding cleaning...

More Small Parts Washer Manufacturers

This piece of equipment is used to clean workpieces of pollutants or debris such as dirt, filth, carbon, oil, grease, metal chips, cutting fluids, mold release agents, ink, paint, and corrosion. To clean, degrease, and dry bulk loads of small parts in preparation for assembly, inspection, surface treatment, packaging, and distribution, small parts washers are used in new production and remanufacturing operations.

Small parts washers can be quite sophisticated, multi-stage equipment with pass-through parts handling systems or as straightforward as the manual "sink-on-a-drum" seen in many vehicle repair shops. In addition, small parts washers are crucial for cleaning fasteners, nuts, bolts, and screws. Small parts washers normally clean parts automatically in a closed cabinet, but pressure washers typically have a single spray jet positioned at the end of a manually operated wand. This classification distinguishes small parts washers from pressure washers. Many steps in the finishing process can be combined into one with the help of this modern industrial technology. Small parts washers can load, wash, rinse, dry, and unload components in an automatic cycle as a part of the production process.

Types of Small Parts Washers

Solvent-Based

In 1954, the first parts washer using solvents were made. The parts washer was an instant hit, so in the early 1960s, the decision not to sell this invention but to lease it to the user and maintain it by replacing the old solvent was made. A settling basin at the washer's bottom holds many gallons of solvent used in solvent-style parts washers. Clean solvent is skimmed off near the top of the settling tank using a small flame-tight electric liquid pump, which then pushes it at low pressure through a stiff flexible nozzle onto a metal grating above the liquid where the metal components rest. Heavy greases that have disintegrated and fallen to the bottom of the tank are covered in dirt. In the past, solvent-based manually operated parts washers employed mixes of oil distillates like gasoline, diesel fuel, lacquer thinner, or kerosene. Still, these are highly volatile and quickly ignite, potentially resulting in an explosion and severe burns to the workers. The solvent-based "tub" washer often features a sizable lid that is held open by a lead fusible link because of this. If there is a fire, the lead will melt, and the lid will crash shut to put it out before it can harm the building. Due to the environmental and safety risks connected with solvent-based systems, there has been a noticeable trend towards aqueous-based systems since the early 1990s

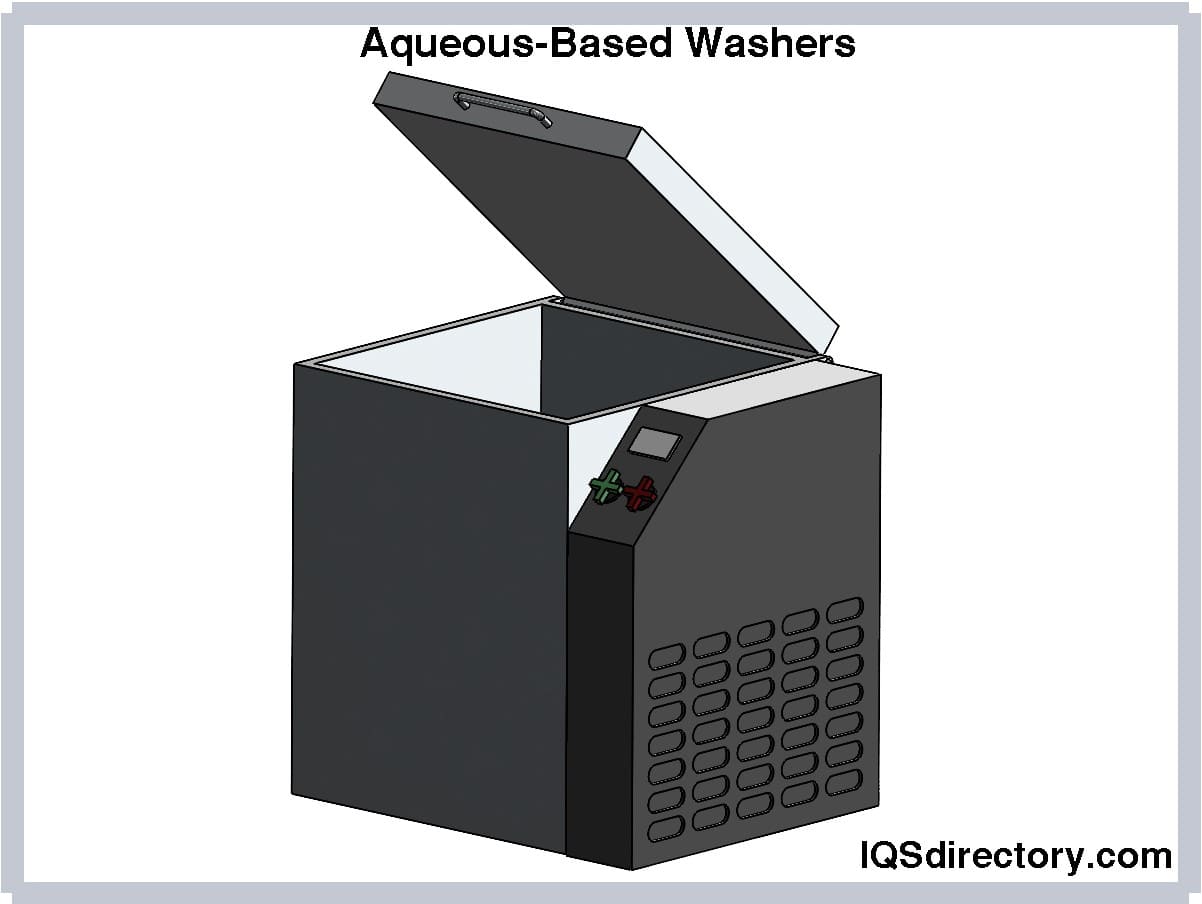

Aqueous-Based

A huge dishwashing machine is similar to an aqueous-based parts washer. Combining heat, mechanical energy, water, and detergent provides the cleaning action. Aqueous parts washers can be divided into two processes: power wash and jet spray. The components are put on a turntable, and the door is shut in a cabinet parts washer. The turntable revolves as a heated solution is flooded or blasted onto the pieces throughout the cleaning procedure. A wash, rinse, and dry cycle is present in many systems. The door is opened, and the components are removed after the cycle is finished. Four things primarily influence the cleaning outcomes in an aqueous parts washer. These elements include time, temperature, detergent, and mechanical energy. These variables can be changed throughout a cleaning cycle to alter the cleaning outcomes.

Small parts washers produce shorter cleaning cycles and less cleaning detergent with high mechanical energy and temperature. Their pump drive system provides mechanical energy. An electric motor in aqueous parts washers typically powers a centrifugal pump. The mechanical energy for cleaning is defined by the mechanical energy given to the wash load, not by the pump's horsepower. The most mechanical energy may be applied to the cleaning process by effectively using the pump motor energy through a well-designed centrifugal pump and paying close attention to the details of piping design and nozzle types. The amount of work a small parts washer does must also be considered. The power density for a given work volume must be consistent among machines of different sizes to produce comparable results. As the work volume increases rapidly on larger diameter machines, this aspect necessitates using pumping systems with significantly higher horsepower.

Power Output

The power density of any parts washer can be used to describe it. The power density is obtained by dividing the total horsepower of all pump systems supplying the wash function by the total work volume for that washing function. The standard measurement is horsepower per cubic foot. This calculation's findings provide a starting point for contrasting alternative parts washing systems. The power density value is also helpful when it is needed to accomplish the same cleaning quality and throughput in a variable work volume. It should be noted that the power density calculation assumes that the wash load receives all of the energy given to the pump, regardless of the efficiency of the pump system. A more accurate power density would consider the pump system's efficiency since efficiency varies substantially even amongst similar pumps and is heavily influenced by the operating point of the pump, the pipe layout, and friction losses in the system.

Small Parts Washer Applications

Metal pieces are cleaned of pollutants such as carbon, grease, metal chips, cutting fluids, and more using small parts washers. They are made to clean minor metal components like nuts, fasteners, and screws. Small parts washers are used by the electronics, automotive, and medical industries to clean equipment, machinery, and other items that require painting, powder coating, zinc coating, lubricants, electroplating, or other surface treatments.

Choosing the Proper Small Parts Washer Supplier

To ensure you have the most productive outcome when purchasing a small parts washer from a small parts washer supplier, it is important to compare several companies using our directory of small parts suppliers. Each small parts washer supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each small parts washer business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple small parts washer companies with the same form.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services