Automatic Parts Washers

Automatic parts washers are mechanical devices designed to rinse, load, dry, wash, and unload parts with the aid of computer software. Automatic part washers minimize manual labor costs and are faster than manually controlled machines. They can also clean parts in high volumes at a much faster rate. Read More…

Alliance Manufacturing, Inc. specializes in the design, engineering, and manufacturing of aqueous parts washers and parts cleaning systems for the industrial products market. Our engineers have developed a full line of aqueous parts cleaning systems, including belt, chain, monorail, and more.

Niagara Systems LLC has offered turnkey custom parts washing systems for over 80 years. With our customization capabilities, our parts washing systems stand out from the competition.

Nobody knows aqueous parts washers as we do! At Better Engineering, we manufacture sustainable Cabinet/turntable parts washers, Inline cleaning systems, conveyor parts washers, ultrasonic parts cleaner, Dunnage wash systems, Drum washers, Carousel washers, Tunnel, and Monorail Parts Washers in the United States using only quality metal. Our systems are built to high-quality standards; we offer...

We are industry leaders and innovators in the world of parts washers. We offer an extensive list of parts washing equipment, from automotive washers to precision washers for medical industries.

Great Lakes Finishing Equipment, Inc. specializes in supplying parts washers for even the most demanding cleaning jobs. Equipment includes table washers, drum washers, aqueous rotary baskets, aqueous belt washing systems, & more. Let our parts washing specialists assist you with your specific washing applications. Contact us today for all of your parts washer needs.

At Automated Cleaning Technologies (ACT), we excel in providing superior industrial parts washers that meet the diverse needs of various industries. Our expertise ensures that no matter your parts specifications, we have the right solution to tackle the job effectively. We take pride in our ability to deliver reliable, high-performance washers designed to handle even the most demanding cleaning...

More Automatic Parts Washer Manufacturers

Automatic Parts Washer Design and Function

All parts washer types, such as spray, agitating, and rotary, that are designed to clean certain products are available completely or partially automatic. They are controlled by computer numeric controlled systems or by computer software.

Automatic parts washers continuously move parts through the wash, dry, and rinse stages. They control the heat, speed, cleaning level solutions, pressure, flow rate, and applied load. All of these options can be adjusted, and they are pre-programmable.

Semi-automatic washers consist of stages that are automated; however, they may require manual unloading or loading with a separate conveyor system. Automatic part washers are usually equipped with a system for recycling. The system helps to minimize costs and protect the environment. In addition, automatic part washers that use computer numeric controlled systems are equipped with one or more storage units and microprocessors.

They also work with computer-aided design software to give the appropriate commands required for the machine to clean the parts thoroughly. The use of automatic part washers has come with numerous benefits. Finally, automatic parts washers reduce solvent use by a greater percentage and maximize cleaning speed and quality, giving higher-quality results at a very low cost.

Types of Automatic Parts Washers

Specific types of automatic part washers are used in industries that process large volumes of components. For example, parts washers meant for the aerospace industry differ from those designed for the automotive industry and other industries.

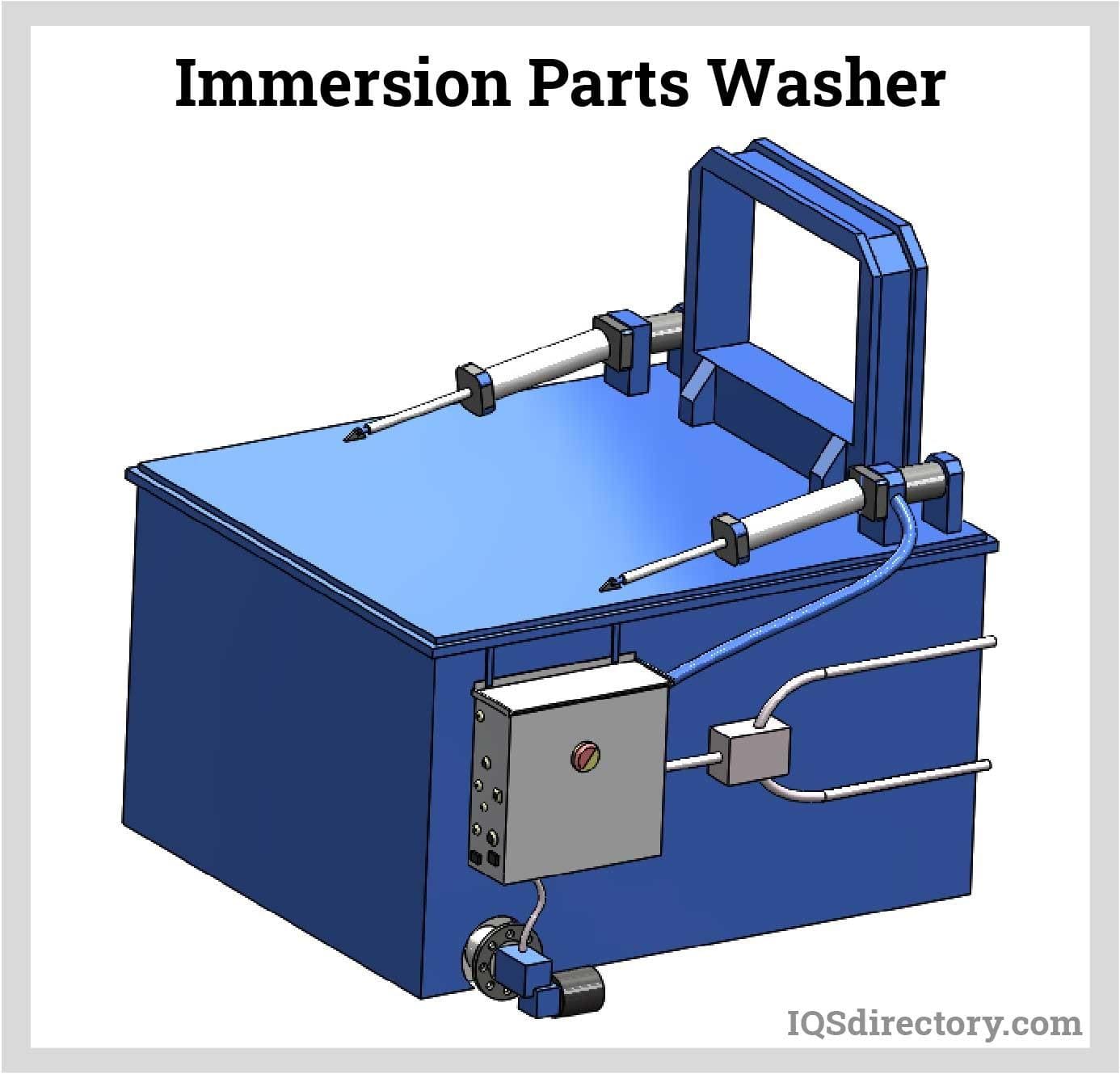

Agitated Immersion Washers

Agitated immersion washers are mostly used when rust, carbon, chips, oil, or buffing compounds need to be removed from parts before being deburred or welded. Immersion washers may consist of a drum washer. The parts are immersed to loosen contaminants and dirt before they are washed by agitation on a tray. Other versions used in advanced industries have multiple tanks attached to them, each having a unique purpose like rinsing, drying, or washing.

Spray Cabinet Washers

Spray cabinet washers are very efficient and work in batches. They are classified as top loading or front loading. Spray cabinet washers consist of a spray manifold that uses a cleaning solution and pressure to clean the parts. Commonly used spray cabinet washers are either roundtable or retractable.

Conveyor Parts Washers

Conveyor parts washers are defined as all-in-one machines. This is because they can perform rinsing, washing, drying, or even sealing if required. There is little human interference when the parts move from one stage to another. Three commonly used conveyor parts washers are the U-bend, in-line, and monorail. All the stages are fully automated, making the cleaning process very easy.

Application of Automatic Parts Washers

Automatic parts washers clean grease, carbon, metal chips, contaminants, and cutting fluids from metal pieces. Automatic parts washers are used in different industries; for example, in the automotive industry, the manufacturers run parts of vehicles that are soiled from making procedures and parts that are used and consist of road dirt, grease, and grime through these automated washers.

Hardware factories producing small tools run their products through part washers in large volumes. They are used in the medical sector to sanitize large amounts of supplies and instruments. In addition, automatic part washers are used in recycling facilities. Before recycling a bottle, drum, or plastic into a new product, it must be completely sanitized and cleaned.

Advantages of Automatic Parts Washers

Automatic part washers can function as a standalone system since they require very little control. Their versatility and customizability are high. Automatic parts washers can be found in various models and designs. Another advantage they offer is that they save space. Many functions and features are offered, ranging from electricity to steam or gas.

Choosing the Right Automatic Parts Washer Manufacturer

To ensure you have the most productive outcome when purchasing an automatic parts washer from an automatic parts washer manufacturer, it is important to compare several companies using our directory of automatic parts washer manufacturers. Each automatic parts washer manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each automatic parts washer business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple automatic parts washer companies with the same form.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services